Shale Glaze

- kathrynstevens

- Feb 12, 2020

- 1 min read

Updated: Oct 5, 2020

Have been testing how to turn the Askam Grog clay into a glaze. Interesting results so far. At 1280 C degrees the material did not melt, so next step is to sieve out the largest pieces of grog and repeat the test.

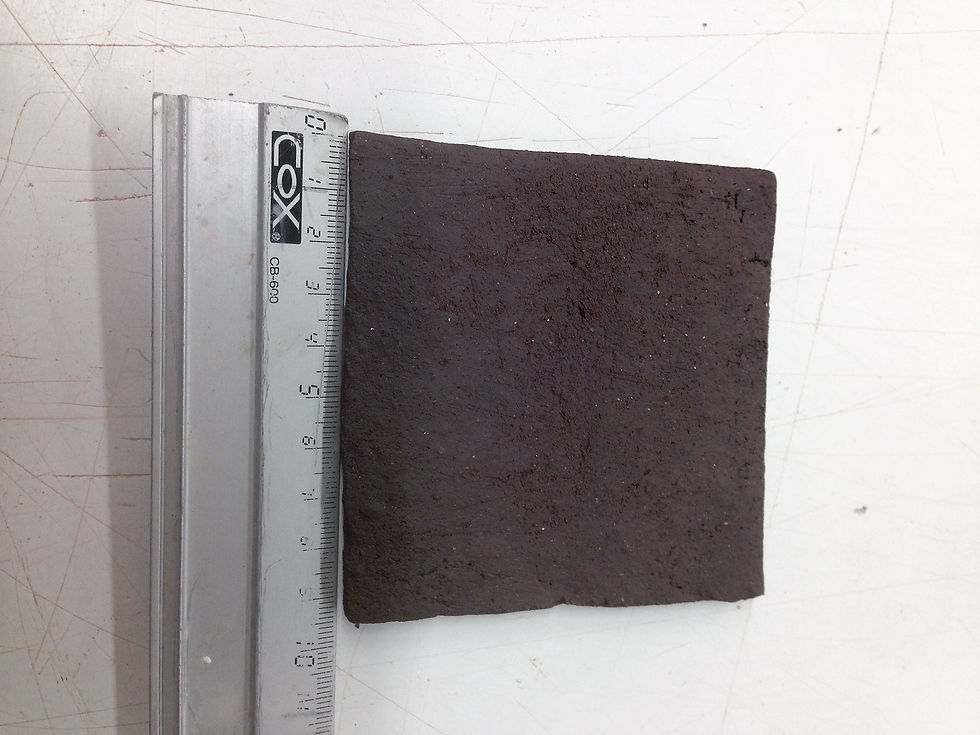

Further work has now been done to reduce the grog within the material and a light glaze has been produced with similar consistency of oxides. The piece below was fired to stoneware oxidation at 1260 C degrees.

The grog was removed using a 40 sieve which left a fine grit feel to the clay. Shrinkage rates have been calculated.

Fired results of the grog texture were successful. As the shale material has not turned into a glaze at high temperature focus has switched to refining a clay body from the raw materials.

Comments